Maintaining a water softener system is essential for ensuring that your household water supply is free from minerals that cause hardness, such as calcium and magnesium. The main way to do this is by remembering to add salt to your water softener.

Adding salt to your water softener is pretty straightforward, but it’s important to follow manufacturer instructions to ensure proper functioning.

The following paragraphs will discuss how and when to add salt, along with the different types of salt that are available for use in a water softener system.

Table of Contents

How to Add Salt to Your Water Softener

Preparing the Brine Tank

Before you add salt to your water softener, you have to prepare the brine tank. Start by locating the tank, which is usually the shorter tank, and check the current salt level. Inspect the tank for any signs of salt bridges, and ensure that the standing water level is below the fill line. Remove any debris or dirt present in the tank to ensure proper functioning.

Removing a Salt Bridge

A salt bridge occurs when the salt in the brine tank hardens, forming a crust that prevents the salt from dissolving. To remove a salt bridge, gently tap around the edges of the bridged area with a broom handle or similar object. Avoid using sharp or metal objects, as they may damage the tank. Once the bridge is broken, stir the salt pellets to ensure uniform mixing.

Choosing the Best Salt

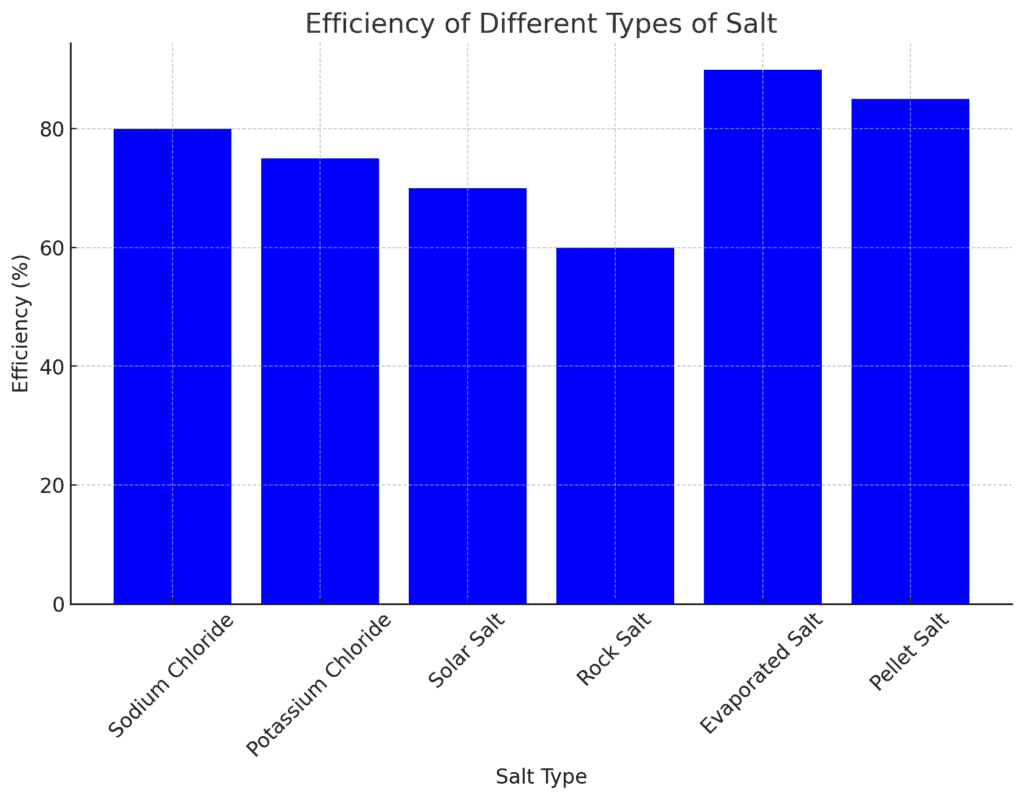

The efficiency of a water softener heavily depends on the type of salt used. There are three common types of salt used in water softeners:

- Sodium Chloride (table Salt)

- Evaporated Salt

- Block Salt

Sodium chloride is the most common and affordable option, but it may not be as effective as evaporated salt which has higher purity. Block salt is a more compact option, but it may not dissolve as easily as the other types.

Always choose a salt type based on your specific water softener and the water hardness level in your area.

Filling the Tank Properly

When you add salt to your water softeners brine tank, remember to follow the manufacturer’s instructions. In general, you’ll pour the salt pellets into the tank and ensure the level remains below the fill line. Monitor the water level throughout this process, as it should not exceed the standing water level recommended by the manufacturer.

Maintaining an adequate salt level in the water softener’s brine tank is essential for its efficient functioning. By preparing the tank, removing salt bridges, choosing the appropriate type of salt, and filling the tank properly, you can ensure that your water softener operates at peak performance, providing softened water for your household.

Understanding Water Softeners and Salt

Water Softener Function

Water softeners are designed to remove hard water minerals, such as calcium and magnesium, from your water supply. These minerals can cause various problems, including scaling in pipes and appliances, soap buildup on surfaces, and reduced efficiency of water heaters. By using a water softener, these issues can be mitigated, and the overall water hardness level can be reduced.

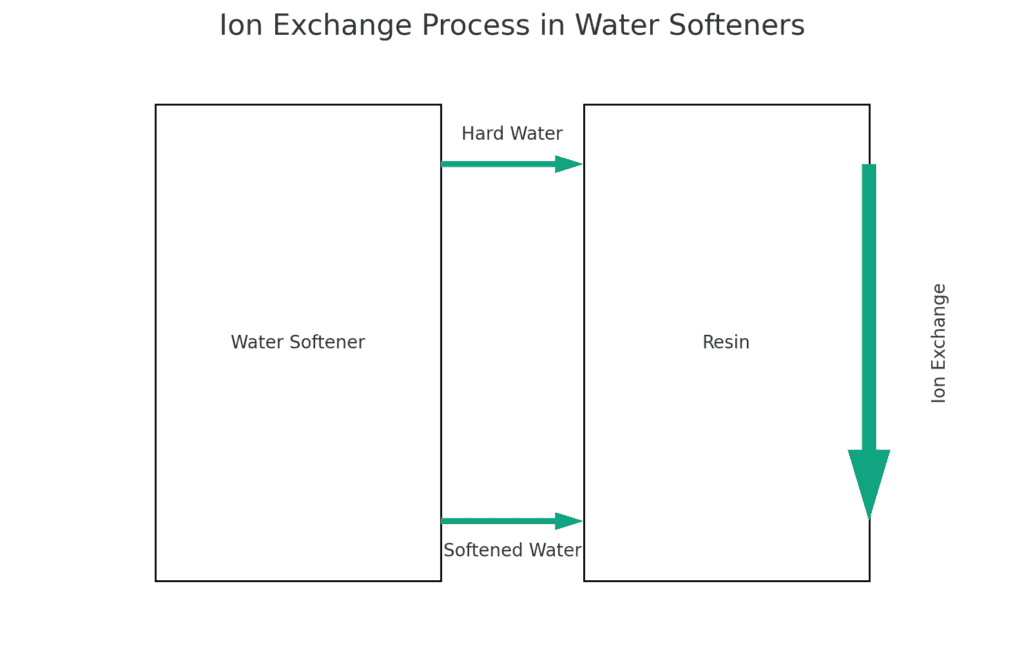

Ion Exchange Process

The primary technology used in most water softeners is called ion exchange. This process involves a negatively charged resin that attracts, traps, and replaces hard water mineral molecules with sodium ions. The resin is housed within the water softener’s tank, and as water flows through the system, the minerals are exchanged for sodium ions in a process that effectively softens the water.

Hard Water Minerals

Calcium and magnesium are the two most common hard water minerals that can lead to a range of issues in households and industrial applications. Water hardness levels can vary depending on the mineral content of the water, and this is determined by factors such as the geology of the region and the water source. By using a water softener that relies on ion exchange, these minerals can be removed, resulting in softened water that is more suitable for everyday use.

Salt is a crucial component in the water softening process, as it replenishes the sodium ions needed for the ion exchange process to continue.

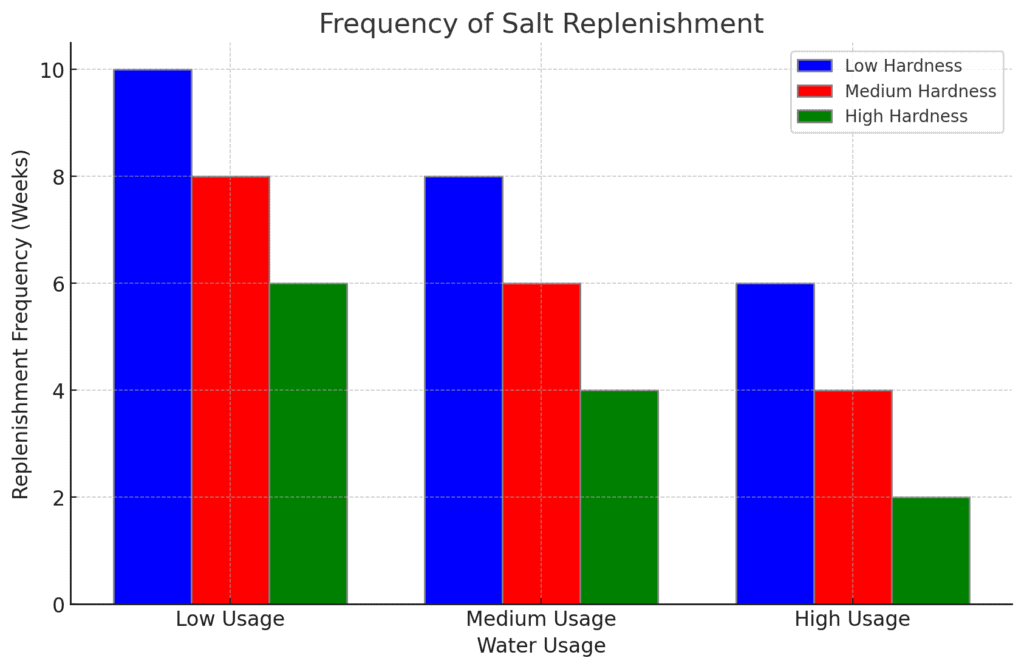

To maintain the effectiveness of the water softener, add salt to the brine tank every 4 – 8 weeks or when the salt level is low. By doing so, you can ensure that your water softener continues to function correctly, providing your household with softened water that is free from hard water minerals.

Different Types of Salt for Water Softeners

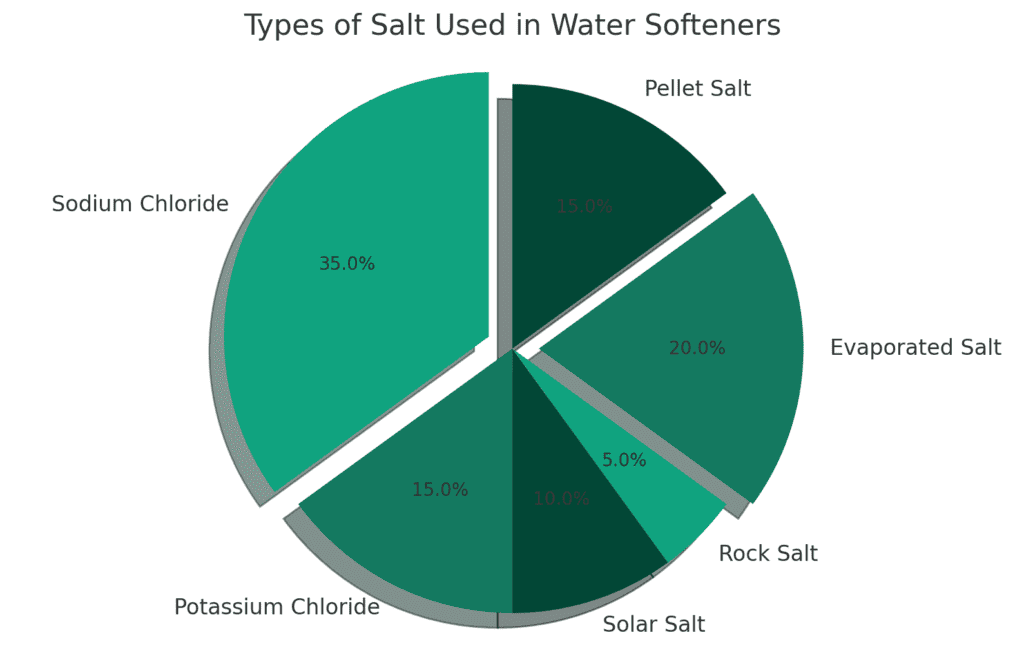

There are various types of salt that can be used in water softeners. Each type has its own characteristics and properties that are beneficial for specific purposes. This article will discuss some of the most common types, including sodium chloride, potassium chloride, solar salt, rock salt, evaporated salt, and pellet salt.

Sodium Chloride

Sodium chloride is the most common type of salt used in water softeners. It is effective in removing calcium and magnesium ions from hard water. Sodium chloride is widely available and relatively inexpensive, making it a popular choice among homeowners. It can be found in the form of crystals, pellets, or cubes.

Potassium Chloride

Potassium chloride is an alternative to sodium chloride for those who are concerned about their sodium intake or have medical conditions that require them to limit their sodium consumption. Potassium chloride works similarly to sodium chloride in softening water but adds potassium ions instead of sodium ones. However, it is more expensive and may not be as readily available.

Solar Salt

Solar salt is a natural product obtained through the evaporation of seawater. It contains about 99.6% purity and is a good choice for water softeners. The salt crystals are large and more slowly soluble than other types, reducing the likelihood of salt bridging in the brine tank. Solar salt is available in crystalline or pellet form.

Rock Salt

Rock salt is a raw, unrefined form of salt that is mined from the earth. It contains impurities like calcium sulfate and has a lower purity level compared to other types of salt. Although less expensive, the impurities in rock salt can potentially cause buildup in the water softener, leading to maintenance issues and decreased efficiency.

Evaporated Salt

Evaporated salt is considered the purest form of water softener salt, with a purity level of nearly 100%. It is manufactured by dissolving raw salt in water and then evaporating the water to leave behind pure salt crystals. This high-purity salt produces less buildup in the softener, preventing salt bridges and ensuring smooth operation. It is available in pellet or block form.

Pellet Salt

Pellet salt is a common choice for water softeners due to its high purity and efficiency in softening water. It is made by compressing evaporated or solar salt into small, dense pellets. These pellets dissolve evenly without causing salt bridges, which can impede the water softening process. Pellet salt can be found in various purity levels, depending on the source material used in its production.

Maintaining the Water Softener

Regeneration Cycle

The regeneration cycle of a water softener is a crucial part of its performance in removing minerals like calcium and magnesium from hard water. During this process, the salt in the brine tank is dissolved to create a brine solution that flushes through the resin bed, where the ion exchange process takes place. The sodium ions from the brine solution replace the hardness minerals attached to the resin, allowing softened water to flow through your home’s pipes.

It is essential to regularly monitor your water softener’s regeneration cycle to ensure optimal performance. Factors like family size, water usage, and the hardness level of your incoming water supply can influence the frequency of regeneration.

Regular Maintenance Checks

A key aspect of water softener maintenance is conducting regular checks, ideally at least once a month, to verify the proper functioning of the system. This includes inspecting the brine tank, checking salt levels, and ensuring there is no mineral buildup in the system.

One issue to watch out for is “mushing,” a phenomenon where the salt in the brine tank forms sludge, making it challenging for the system to dissolve the salt effectively. This can lead to insufficient brine for the ion exchange process and reduced water softening efficiency. Using a high-quality salt, such as potassium chloride or salt pellets, can help prevent mushing.

Salt Delivery and Demand

A water softener requires a consistent salt supply to function correctly. Most systems require a 40-pound bag of salt every 4 – 8 weeks, depending on factors like household water usage and water hardness levels. A family of four, for instance, with a moderate water hardness level might need to replenish salt every six weeks.

Some modern water softeners come equipped with alert systems or smartphone apps that notify when the salt levels are low, ensuring timely replenishment.

Addressing Water Quality Issues

While water softeners are designed to remove hardness minerals, they may not address other water quality issues, such as contaminants or bacteria. If you have concerns about your water quality, it is essential to conduct regular testing and consider additional water treatment systems.

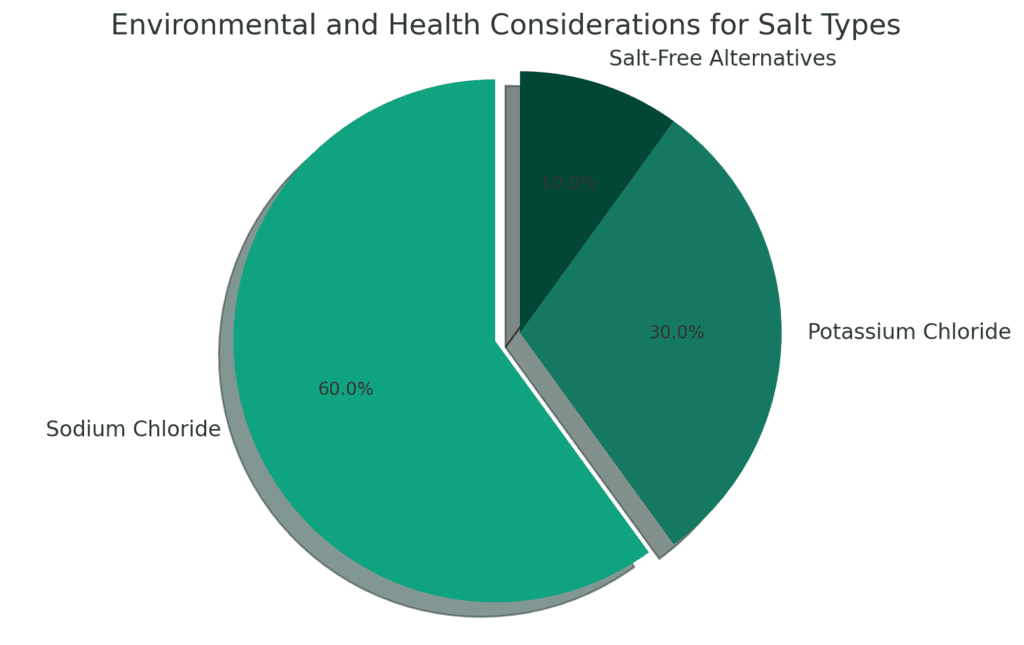

Environmental and Health Considerations

Alternatives to Sodium Chloride

While sodium chloride is commonly used in water softeners, there are alternatives that can minimize the environmental and health impacts.

One such option is using potassium chloride as a substitute for sodium chloride. Being chemically similar, potassium chloride can soften water just as effectively but without adding extra sodium ions into the water supply. This can be especially beneficial for those on a low-sodium diet or with specific health concerns.

Besides potassium chloride, there are also salt-free water conditioning systems that use alternative technologies such as nanofiltration or template-assisted crystallization.

Water Usage Efficiency

The efficiency of water usage is another crucial factor to consider when it comes to environmental concerns. Traditional water softeners regenerate through a backwashing process that consumes a significant amount of water.

By selecting a water softener with higher efficiency, you can significantly reduce water waste. Modern water softeners often come with features such as demand-initiated regeneration, which regenerates the resin based on actual water usage instead of a predetermined schedule. This can lead to a more efficient use of water and less waste.

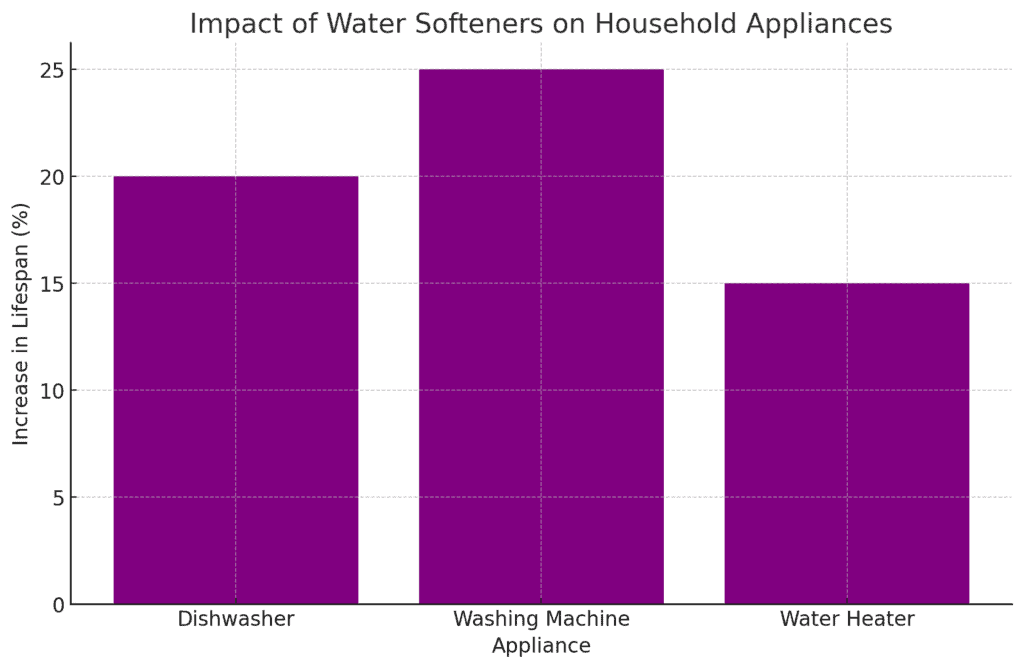

Impact on Household Appliances

Using water softeners to treat hard water can extend the lifespan of household appliances like dishwashers and washing machines. The removal of calcium and magnesium ions from the water can prevent mineral buildup, which can clog pipes and reduce water pressure. Moreover, it can help maintain the energy efficiency of appliances by preventing the formation of scale deposits on heating elements.

Evaluating the Water Softening Capacity

Hardness Testing

To determine the appropriate amount of salt needed for a water softener, the initial step is to test the water hardness level. This can be performed using a hardness test kit, which provides a clear indication of the water’s calcium, magnesium, and mineral content.

Regularly monitoring the water hardness levels in a home can help ensure that the water softener is operating at its optimal softening capacity, providing users with better water quality.

Examining Glassware and Kitchenware

Another method to evaluate the effectiveness of a water softener is to observe the condition of glassware and kitchenware washed and used within the household. Excessive mineral deposits or spots on glasses and dishes may indicate that the resin in the water softener is not adequately softening the water.

This can lead to an increase in the required amount of pellet salt or evaporated salt pellets for improved water quality.

Assessing Cleaning Challenges

In addition to examining kitchenware, it is crucial to assess the overall cleaning challenges faced within the home. Hard water can lead to a number of issues, such as reduced water pressure, mineral buildup in pipes and fixtures, and a less efficient cleaning regimen.

Regularly evaluating the cleaning process and any associated difficulties can provide valuable insights into the water softener’s performance.